How To Clean Skateboard Trucks: Care Guide

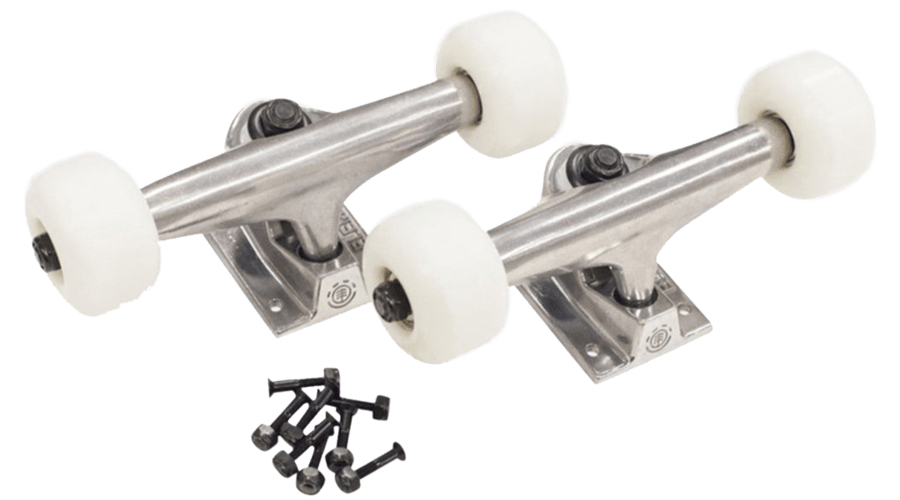

Trucks are arguably the longest-lasting piece of equipment in your skateboard setup.

Caring for your skateboard trucks can mean the difference between feeling in or out of control as you ride down the street or drop into the park.

Read on to learn about proper skateboard truck maintenance and what you can do to keep your skateboard rolling at its best.

Regular Maintenance Routine

Skateboard trucks are made up of several interconnected parts which all need to be free of dirt to work properly. There are a few key areas that are prone to gunk buildup; the axles, the bushings, and the pivot cup.

Perform the following maintenance routine at regular intervals to maximize the life of your trucks and keep them working smoothly:

Truck Inspection

Begin by flipping your board over to get a good look at the trucks, then check the following items on each of your trucks:

- The baseplate – Check if any micro-cracks have developed and that each of the four screws are properly tightened down with their nuts.

- The pivot cup and bushings – Check to see if they look dry and if any cracks have developed. Bushings are the part of your skateboard trucks that are likely to wear out the fastest.

- The bushing washers – Check that they are in good shape and are not cracked.

- The axle – Check that the axle isn’t bent and check the ends of the axle where your wheels are attached – the threading should still be in good condition, if it’s not, you might want to rethread your axles. You can do this yourself if you have the tool, or head to your local skate shop.

- The hanger – Check that you haven’t ground through to the axle.

If any of the parts above need replacing, keep reading to learn what to do.

Routine Cleaning

Routinely cleaning the dirt and gunk off of your trucks will help them last longer and perform better. The main areas to keep clean are:

- Axle

- Bushings

- Pivot cup

You’ll need the following tools for routine cleaning:

- Skate tool

- A couple of clothes or a paper towel

- Water

- WD-40

The following steps will guide you through routine cleaning:

- Use a damp cloth to wipe the bushings and the bushing washers. Use a toothbrush to get the hard-to-reach places.

- Dry the bushings with a dry cloth or paper towel.

- Repeat this same process with the pivot cup.

- Next, loosen the axle nuts and remove the wheels and washers from your trucks.

- Spray some WD-40 on a cloth or paper towel and wipe down the axles. You will likely remove a lot of dirt from this area. Wipe the area where the hanger meets the axle.

- Wipe down with a dry cloth and reinstall your wheels.

If there is an excess amount of dirt or the appearance of rust, you’ll want to perform a deep clean.

Adjustments

Once your skateboard has been inspected and cleaned, it’s time to adjust your truck settings.

Adjusting your skateboard trucks is important for personalizing your setup. Each truck has three nuts that should be adjusted:

- The two-axle nuts – which hold your wheels onto the trucks.

- The kingpin nut – determines the “tightness” or “looseness” of your trucks along with the harness of your bushings.

The axle nuts should be tightened to the point of preventing the wheels from moving side to side while also making sure to not pinch the bearings and affect the spinning of the wheels.

The kingpin nut can be as loose or as tight as desired.

- A loose kingpin nut will prioritize agility over stability in allowing the board to turn with ease.

- A tighter kingpin nut will provide more stability and less manoeuvrability.

Deep Cleaning Skate Trucks

For the best truck performance, you can perform a deep clean. Deep cleans require some time for disassembly, cleaning and reassembly, but they also provide the perfect opportunity to inspect your parts.

Uninstalling and Disassembling Skate Trucks

The first step is to uninstall your trucks. For a step-by-step guide on how to install and uninstall your trucks from your skateboard deck, check out our article on "How To Set Up Trucks".

Once the first step is completed, you’ll want to disassemble your trucks with the following process:

- Take off the wheels by unscrewing the axle nuts. Be sure not to lose the axle washers on each side of the wheel.

- Remove the kingpin nut which will allow the whole assembly to come apart.

- Remove the top bushing and bushing washer, pull the hanger up and move the pivot out of the pivot cup.

- Remove the remaining bushing and bushing washer.

- Use a screwdriver to pry the urethane cup out of the pivot cup.

Once the pieces have been disassembled you are ready to start your deep clean.

After the deep clean has been completed, reassemble your trucks by reversing the steps listed above.

Deep Cleaning Your Skate Trucks

You’ll need the following items to clean your trucks:

- Skate tool

- Wire brush and/or toothbrush

- Water

- WD-40

- A couple of clothes or a paper towel

Keep the following things in mind while cleaning your trucks:

Clean the urethane parts, the bushings and the pivot cup, with water.

Clean the metal parts with a cloth sprayed with WD-40.

Ensure that all parts are dry before reassembling.

To clean the urethane parts:

- Use a damp cloth and rub them until the dirt is gone. Dry them off with a dry cloth.

- Check for cracks and signs of wear.

To clean the metal parts:

- Spray a cloth with WD-40 and rub the parts until they are clean.

- Pay special attention to cleaning the axle as this is an area that is prone to picking up the most dirt.

- Don’t forget to clean inside the pivot cup.

- Check for cracks and signs of wear.

- Dry the parts with a dry cloth.

Once all the parts have been cleaned and dried, reassemble the trucks as described above.

If your trucks have excessive rust or a spot of rust that will not come clean, try the process in the next section.

How to Clean Rust Off Skateboard Trucks

If trucks have been sitting for a long time or have come into contact with water and left unattended, rust can form.

Rust should be removed as soon as it’s noticed as it can spread and weaken the integrity of your skateboard trucks if left untreated.

To remove rust:

- Disassemble your trucks and submerge the rusty parts in WD-40 for a few minutes.

- When ready, remove the pieces and wipe them off with a cloth.

- The rust should come off easily and if not, repeat the process leaving the parts submerged a little longer.

- Use a toothbrush to dislodge any stubborn rust and use a more strongly bristled brush or steel wool as a final measure.

Once all the parts have dried off, reassemble your freshly cleaned trucks.

Signs for Part Replacement or Repair

Skateboard trucks are modular and every part can be replaced, which helps save money.

If replacing parts using pieces from old trucks, be sure to use pieces from the same brand as different brands might have slightly different shapes.

The most common parts that will need replacement are:

- Bushings – Check for cracks or stress marks.

- Worn-out bushings can lead to less rebound and a more “floppy” feeling in your skateboard.

- Bushings cannot be repaired and should be replaced with new ones.

- Axles – Check the threaded ends of the axles.

- The threads sometimes become worn making it difficult and frustrating to adjust the axle nuts when changing wheels.

- Although axles can’t be individually replaced, they can be rethreaded with the right tool.

It’s time to buy a new set of trucks if:

- The axle is bent or broken.

- The pivot snapped off the hanger.

- The baseplate is cracked.

Other signs to look out for are grinding or chattering sounds while rolling. If you’ve checked your trucks and don’t see any signs of damage, you’ll want to inspect your bearings.

For details on how to inspect and maintain bearings, check out our article on "How To Care For Bearings".

Proper Storage and Transportation

Storing the Skateboard with Trucks

When winter or the rainy season starts to show up and you don’t have access to an indoor skatepark, it’s time to put your skateboard in storage.

To ensure your skateboard doesn’t suffer any damage while not in use, be sure to store it with the following things in mind:

- Store your board vertically. If storing the board horizontally, be sure not to stack anything on top of it so you don’t soften the deck.

- Store your board in a climate-controlled area to avoid large shifts in temperature or humidity that can warp or damage your deck.

Transporting the Skateboard with Trucks

When travelling with your skateboard, it’s a good idea to use a protective bag or case.

The protection isn’t so much for your skateboard as it is for the things around it. Skateboard trucks can scratch the things around them if not covered.

A dedicated skateboard bag gives the added option of carrying an extra deck, set of bearings, or curb wax so you’re extra prepared at your next skate destination.

Troubleshooting Common Issues

Loose Trucks

One of the most common issues in skateboard maintenance is the need to adjust truck tightness.

- Loose trucks favour manoeuvrability over stability.

- Tight trucks favour stability over manoeuvrability.

Use a skate tool to adjust the kingpin nut to the settings that suit you the most.

If the trucks still aren’t delivering the desired performance after adjusting the kingpin nut, the next solution is to change out the bushings.

Bushings are rated as soft/medium/hard and have an impact on turn radius and response.

- Soft bushings favour manoeuvrability.

- Hard bushings favour stability.

Wheel Bite

Wheel bite is when the skateboard wheel pinches the deck during a turn and abruptly stops rolling. The result is that the skateboard stops and the skateboarder doesn’t.

The solution is to:

- Adjust the tightness of the kingpin nut, or

- Use riser pads

More info on riser pads can be found in our article on "How To Choose Skateboard Trucks".

Try the following “wheel bite test” before heading out with your adjustments:

- Turn your board over so that the trucks are facing upwards.

- Put the two palms of your hands on the two wheels and alternatingly push each wheel towards the skateboard deck.

- Check if the wheel touches the deck. If it does, troubleshoot as described above.

Uneven Truck Wear

Due to the nature of skateboarding, our weight is often unevenly distributed on the board, resulting in unbalanced wear on the urethane parts of your setup; notably the bushings and wheels.

If you’re into grinding and do 5-0’s than nose grinds, keep an eye on the uneven wear on the hangers of your trucks. To help your equipment last a little longer, consider rotating your wheels and swapping your trucks, front to back, from time to time.

Another area that gets worn out over time is the four hardware holes in each baseplate. These holes can “stretch out” over time leading to loose trucks. The solution is to regularly check and keep your hardware tight, or buy a new set of baseplates.

Caring for your skateboard trucks protects your investment by helping your equipment last longer. Routine maintenance helps your equipment work more efficiently so you skate better. Knowing how to perform a deep clean when needed, and when to replace a broken part will keep your setup rolling for many days ahead.

Related Guides

How To Choose Your Skateboard Size

How To Choose Skateboard Bearings

How To Choose Skateboard Wheels

How To Choose Skateboard Trucks

How To Choose Skateboard Grip Tape

How To Clean Skateboard Bearings